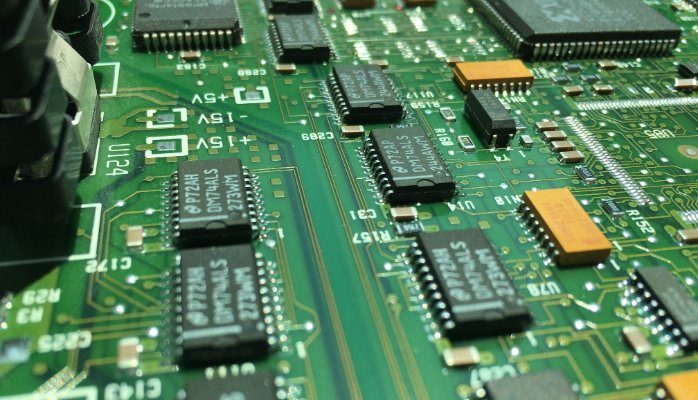

It is an easy question, but the answer is far more difficult. Cokeva has been in business over 25 years repairing failed electronic assemblies, so it is a question we answer on a daily basis. The assemblies I am talking about all worked at one time. They were in service, then something changed and they failed. I grouped the answer to why do electronic assemblies fail into a few categories;

The Parts Fail – Some parts have a limited life, like batteries, relays, electrolytic caps. Often time when these parts fail, they simply exceeded their expected lifespan. Another common cause is that the constant changes in temperature and the differences in coefficient of expansion of the different materials that are used in a part, cause a marginally made part to fail, after years of use.

Manufacturing Defect – Solder is what is commonly used to attach components to boards. It takes very little solder to make an electrical connection; it takes far more solder and a quality solder joint to make a good mechanical connection. The manufacturing process typically tests for the electrical connection, but not a mechanical one. Temperature cycles, shock, vibration can cause a marginally assembled board to fail.

Marginal Design – When an assembly is manufactured it is almost always functionally tested; it is run through diagnostics that mimic how it would be used in daily operation. Rarely do manufacturing tests verify the limits of the operating parameters (this is done at the design stage). With all the variables of the parts being used and the operating environment, there is a significant possibility that some assemblies will work in some conditions, yet not in others. This is believed to be a big contributor to the “no trouble found” problem in the industry.

External Influences – Often time electronic assemblies see a harsh environment. Voltage spikes from the line, mechanical shock, liquids being spilled on it, extreme temperatures, dust “bunnies” that block the vents, corrosives, like leaking batteries and electrolytic caps. This is a quick list of external factors that we see that cause electronics to fail.

While there can be a number of reasons an assembly fails in the field and the above list certainly isn’t all encompassing, it is important to understand why product is failing, to prevent its re-occurrence, if at all possible.

Article by Ken Ueltzen

Recent Comments